No one wants a landfill in their backyard. Certainly, no one wants emissions from these landfills to contaminate air, soil and water with toxins and greenhouse gas emissions. But that’s exactly the place where almost all post-consumer flexible packaging ends up. The industry claims that the flexible packaging is ‘eco-friendly’, because it takes less space in landfills, as a flexible pouch weighs around 9gms compared to a PET bottle 35gms and a 330ml glass bottle around 220gms.

As I have argued in my previous article, we talk about billions and billions of pouches ending up in a landfill or an incinerator, where in both cases valuable material is wasted. They might take up 75% less space in a landfill but still there they don’t degrade within a million years, due to its complicated and variant composition of plastic and adhesive layers. The only proper answer is: Recycling.

But with all the promotion in favour of the flexible packaging there is no proper recycling system available. Sonoco Recycling, one of the largest recyclers with 50 locations worldwide, currently operates six material recovery facilities (MRFs). Despite its continuous investments in updates Sonoco’s facilities are still unable to accept post-consumer multi-layer flexibles. It is one of the realities the flexible packaging industry faces, simply said, there is no facility in the world for the recycling of post-consumer multi-layer flexible packaging. This is obviously an handicap for the consumer goods companies as they only can claim their “change to more eco-friendly packaging”, based on its lightweight, less use of resources, and only can boast about flexibles taking less space in landfills. That’s all nice and dandy but they never can claim its recyclability, something the consumer in these days requires to see. Neither incineration nor entombing in a landfill adds to the sustainability or useful life of the multi-layer packaging.

The parameters of the recycling process of post-consumer multi-layer flexible packaging

When we started to design a recycling solution for post-consumer multi-layer flexible packaging we had to take into account several parameters.

First of all, the keyword for the recycling process is “post-consumer”. Although the intention is to take-in post-consumer packages as clean as possible by organizing selective collection (about that in part 03 of this series) we have to be realistic and face the fact that quite some post-consumer residue, i.e. product rests, has to be removed, before the material effectively can be recycled.

Tests showed us that the degree of contamination due to product residues is somewhere between 10 and 20% of the total weight, which sounds high, but isn’t in absolute terms, as the average weight of a flexible pouch is 10gr, which translates into 1 or 2gr of residues, i.e. processed food (tomato sauce, mayonnaise, soups, oils etc.), cosmetics and detergents (shampoo and others). We have to reckon with the possibility that any product residue might be involved in the process.

The second parameter is, that since many flexible packaging feature dosing mechanisms, zippers, drinking spouts or screw caps it is not to be expected that the consumer provides cleaned or rinsed pouches. Due to these caps and spouts a forcible washing process in a hydro-cyclone isn’t a solution as we also take into account that due to the sticky residues the pouches don’t open easily.

The third parameter is the absolute lack of consistency in the intake of post-consumer flexibles. We have tested the intake of flexibles in several cities and have to conclude that although there is no consistency in product residue, there is an almost Gaussian distribution (Gaussian bell curve) in terms of the products and brands used by the consumer. This is of importance as we intend to recycle the product residue of the flexibles into biogas to be used in the recycling process itself. (About this later)

Furthermore we had to set our goals in relation to its feasibility and the economic, technical and environmental aspects. The recycling centre as described here is based upon the following criteria:

1. The set-up is a modular design for a small-scale recycling centre, intended to implement in any urban area of 2-4 million inhabitants/consumers. The reason we choose for a relatively small-scale local unit is that in our opinion the logistic lines (supply of post-consumer pouches) should be kept as short as possible, as we prefer the post-consumer pouches not to be pressed in bundles to reduce its volume for the long haul. Furthermore a local unit stimulates community involvement for selective collection and consequently diminishes the waste volumes on the local landfills.

2. We are not recycling into pellets, and our end-goal is not blow-moulding, injection moulding or extruding with a recycled resin. That can’t be done as our intake (multi-layer pouches) have a wide variety of material compositions, impossible to sort out and bring back to resin of any high-quality.

3. What we do however is creating a composite film with excellent chemical and mechanical properties from which a wide variety of high-value durable consumer products can be created.

The set-up of a recycling centre, according to the criteria stipulated above, can handle post-consumer flexible packaging, such as multi-layer plastic pouches, chocolate and candy wraps, flow-wraps for cookies, biscuits and similar, and chips bags. All these items can have a structure of several types of plastic, aluminium (foil) and metallized film in any combination.

Note: It is funny to say, that when we developed this recycling system, we realised that it would be very easy (and profitable) to incorporate a second mainstream of post-consumer packaging namely laminated paperboard packaging, such as beverage cartons (TetraPak, SIG and EloPak), beverage cans made from paperboard (Lamican, CartoCan) and laminated or waxed folding cartons used for frozen food, ready-meals, and similar products. To this recycling stream blister packs with a paperboard/plastic structure can be added.

However we restrict this description of the recycling process to the post-consumer flexible packaging.

Recycling of Flexible Packaging

Actually, the recycling line for flexible pouches is nothing special and is constructed using known techniques and existing technologies, taken from other industries and with some engineering modifications and additions made suitable for our purpose.

As said, the objects to be recycled are post-consumer flexible pouches. The keyword is post-consumer. In other words the pouches to be recycled have a certain degree of contamination by product residues, i.e. processed food (tomato sauce, mayonnaise, etc.), cosmetics and detergents (shampoo and others). We have to reckon with the possibility that any product residue might be involved in the process.

Since many flexible packaging feature dosing mechanisms, zippers, drinking spouts or screw caps a forcible washing process in a hydro-cyclone isn’t a solution as we also take into account that due to the sticky residues even the pouches without any fitments don’t open easily.

The only solution is, before the washing cycle, to cut the material into the narrow strips we need for our recycling process. In order to avoid excessive pollution of the shredder we have projected special high-pressure water nozzles in the shredder, and use a screw conveyor with a forced downwards water flow while the strips are transported. The auger brings the strips on a woven dewatering belt, where with hot air the material is dried, after which they fall into a storage tank.

The contaminated process water from the shredder with the solid residue particles is pumped to a sedimentation tank to partly be recycled and brought back into the washing line and partly be transported to the biogas digester.

The in narrow strips shredded and washed flexible packaging material (a mixture of various plastics, aluminium and metallized film) is the raw material for the second step of this recycling process, which is the manufacturing of plates, sheets or slabs as intermediates for the planned final consumer durables.

In order to achieve this result it is necessary that the strips are brought into a state between solid and liquid. The plastic strips are not allowed to melt, but they should be soft, not sticky, to be able to fuse with each other and the aluminium into one homogeneous body, using heat and pressure. For this purpose the storage tank is heated and equipped with a slowly rotating mixer arm, which ensures a consistent mixture. In addition, an additive is added.

The additive, about which I will not divulge more details, it is an organic waste product of a certain manufacturing process, which, after washing and shredding is mixed in a certain ratio with the strips. The additive gives a boost to the final product, which will become harder, more homogeneous, elastic and stronger.

From the storage tank this mixture is deposited on a conveyor belt through a vibrating dosing unit in a 5 to 50 cm thick uniform and continuous layer. The thickness of the layer depends on the application of the final product. The conveyor belt is an integral part of the hot-press.

The technology we borrowed from the rubber industry, where shredded tires are mixed with urethane glue, producing rubber pads for stalls and truck beds. Note, that we don’t use glue, only heat and pressure.

The press, we have projected is a so-called “belt feed press”. The material is deposited on the wire mesh belt as it moves into the press. A shaker and levelling screen evens out the mat and each time the belt is filled with loose material, the press closes and fuses the material. The finished mat slides onto a cooling table to be sheared into large panels as the next batch is pulled into the press, overlapping at the ends making a continuous thick composite film.

Tests showed that we need pressure up to 200 psi, which at a temperature of 350°F (175°C) delivers in one press-stroke of 6 minutes a 12’ (3.65 m) section of the composite film at a width of 6’ (1.80 m).

This recycling line now has produced two separate products:

1. Plastic/aluminium composite film in a thickness of 5 to 50 mm

2. Contaminated process water with solid product residues (food, cosmetics residues etc.)

It should be clear, that out of the formed composite film a large variety of products can be pressed. To this end, the continuous composite film is cut into large (p.E. 4′ or 1.20 m) sections, which are successively fed one at a time into a cold press. In this cold press the still hot material gets its final shape and dimensions. Here the necessary corrugation, recesses, channels and embedding are pressed in the material.

After the cold press a conveyor belt runs the prepared panel to the manual assembly and finishing line.

The range of products that can be manufactured run from the simple ones to the more complicated and more high-valued items. In several production runs in Brazil we have manufactured corrugated roof panels.

Compared to the existing (asbestos, aluminium, galvanised steel or concrete) roof panels, the panels made from recycled film material have far better characteristics, such as light weight, good isolation, mechanical and chemical resistance, are unbreakable and have a low noise level. Although basically a lower-value item, the corrugated roof panels are very popular in low-income countries where they are used in housing projects, while in industrialised countries the recycled corrugated roof panels will be very popular in the agriculture industry, particularly for poultry sheds and other animal stables and barns, due to their excellent heat isolation.

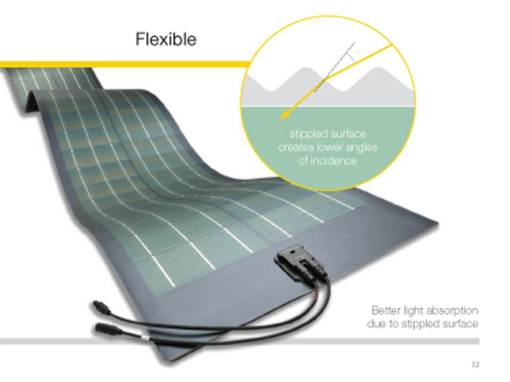

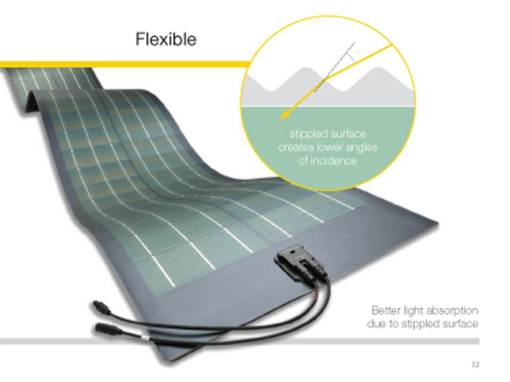

Talking about the agriculture sector there is another item of interest, which can be manufactured from the composite film. That is low-cost solar panels, which can easily be mounted on top of the above mentioned corrugated roof panels. This is an important item as farms raising pigs, poultry as well as cattle use a large quantity of energy for the ventilation, heating/cooling, and all ancillary equipment.

In this case, after the cold press in which the composite film is pressed into its right shape as solar panel, a conveyor belt runs the freshly pressed solar panel to the manual assembly line, where the thin-solar film is glued into the embedding and the cables and connectors are installed.

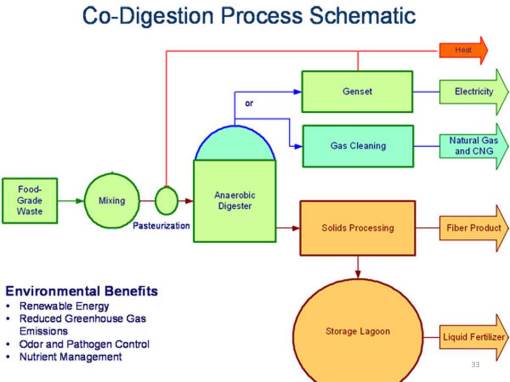

To complete the sustainability of this recycling centre we projected that the process water with the solid product residue is pumped to a sedimentation tank for further processing in the biogas plant and partially treated, and recycled as process water (closed loop).

Small-scale bio-gas digester

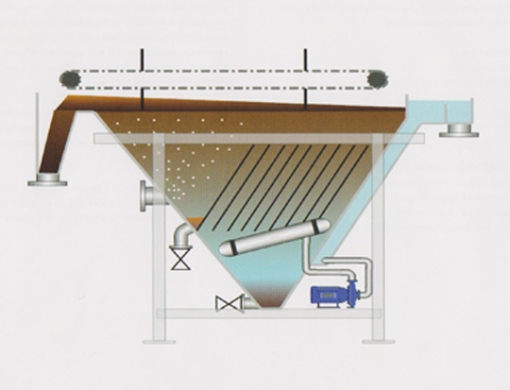

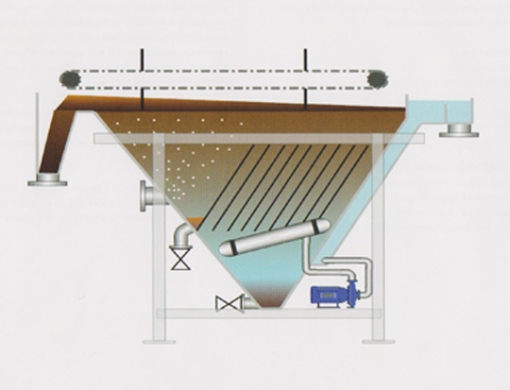

The process water with the solid product residue is pumped to the sedimentation tank, and from there to an Optiflot, in which the contaminated water is slowed down and the separable particles will float to the surface. The floating particles will be removed automatically and continuously by a scraper mechanism. A lamella plate pack is installed to increase the separation area of the unit and ensures that even the smallest flocs are removed from the waste water.

Optiflot, in which the contaminated water is slowed down and the separable particles will float to the surface

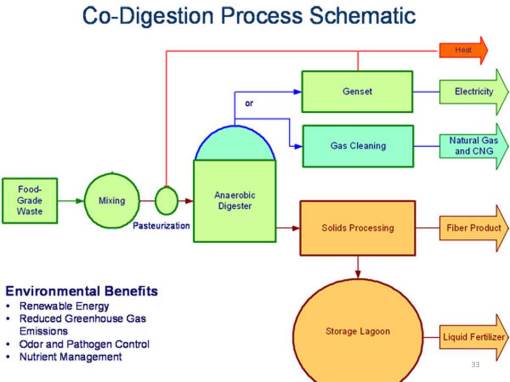

With a 30-days fermentation process, the collected solids are pumped in the bio-digester once in a month. The contaminated process water goes through a series of Recycle Storage Tanks and after polishing the process water is re-pressurised for discharge in the wash process of the recycling lines.

The solids undergo an anaerobic digestion widely used as a source of renewable energy. The process produces a biogas, consisting of methane and carbon dioxide. This biogas can be used in combined heat and power gas engines (CHP) or upgraded to natural gas quality bio-methane. The nutrient-rich digestate that is also produced can be used as a (biological) fertilizer.

Besides the products made from the composite film, this recycling process also supplies us via the biogas digester: liquid fertilizer, dry fertilizer and natural gas that is intended to be used for heating the drying process as well as in the belt feed press.

According to information from the AMI (agricultural market information service) in Bonn/Germany, the world produces nearly 1.5 billion tonnes of fruit and vegetables, of which 800 million tonnes vegetables and nearly 700 million tonnes fruits.

According to information from the AMI (agricultural market information service) in Bonn/Germany, the world produces nearly 1.5 billion tonnes of fruit and vegetables, of which 800 million tonnes vegetables and nearly 700 million tonnes fruits. Innovations in packaging technology can overcome this challenge by providing extended shelf life and reducing accumulation of product decomposition liquids in the packaging bottom. An important part of the process is the product’s respiration, in which the product consumes oxygen and expels carbon dioxide, water and heat. In this way, carbohydrates and other substances important to the product’s freshness, taste and health quality are broken down.

Innovations in packaging technology can overcome this challenge by providing extended shelf life and reducing accumulation of product decomposition liquids in the packaging bottom. An important part of the process is the product’s respiration, in which the product consumes oxygen and expels carbon dioxide, water and heat. In this way, carbohydrates and other substances important to the product’s freshness, taste and health quality are broken down. As was expected Fruit Logistica had some interesting packaging innovations on offer. I just made a selection of what I thought to be exceptional. Let’s walk around the various booths and describe the best. Here we go, starting with fresh vegetables.

As was expected Fruit Logistica had some interesting packaging innovations on offer. I just made a selection of what I thought to be exceptional. Let’s walk around the various booths and describe the best. Here we go, starting with fresh vegetables. The Israeli company Hefestus Ltd., established in 1993, takes the MAP technology a step further with its SLB – Shelf Life Booster technology. The Hefestus’ MAP sealers have only one fully automatic vacuum-free SLB sealing head. Without creating a mechanical vacuum the system protects texture and appearance, so that even the most delicate “vacuum banned” goods can be handled, extending the product’s shelf life without the need for preservatives or freezing, thereby enabling storage and delivery of goods chilled or at room temperature.

The Israeli company Hefestus Ltd., established in 1993, takes the MAP technology a step further with its SLB – Shelf Life Booster technology. The Hefestus’ MAP sealers have only one fully automatic vacuum-free SLB sealing head. Without creating a mechanical vacuum the system protects texture and appearance, so that even the most delicate “vacuum banned” goods can be handled, extending the product’s shelf life without the need for preservatives or freezing, thereby enabling storage and delivery of goods chilled or at room temperature. Peakfesh is said to be bio-degradable (no material specification is given) and has permission to also be used for organic and EKO products.

Peakfesh is said to be bio-degradable (no material specification is given) and has permission to also be used for organic and EKO products.

Currently used filling lines only need simple modifications to process the paperboard cans as standard aluminium pull up can tops are used. This newly introduced production system is said to save up to 30% of the production costs.

Currently used filling lines only need simple modifications to process the paperboard cans as standard aluminium pull up can tops are used. This newly introduced production system is said to save up to 30% of the production costs. Sonoco’s solution was a rigid paper container with metal ends that offers the same product appearance and protection for liquids, but at a lower cost and using far more sustainable materials. According to Sonoco, the screw-top, paperboard can is durable enough to last the required product’s four year shelf life.

Sonoco’s solution was a rigid paper container with metal ends that offers the same product appearance and protection for liquids, but at a lower cost and using far more sustainable materials. According to Sonoco, the screw-top, paperboard can is durable enough to last the required product’s four year shelf life. Now start thinking. Use your imagination.

Now start thinking. Use your imagination.

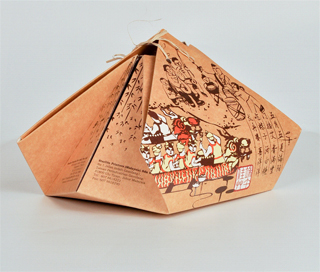

The recent past has seen very interesting creations in folding cardboard or better still folding paperboard. It is as if the Japanese origami culture and the traditional Chinese paper cutting have influenced many a packaging designer. This means that some packages made from paperboard have the most fantastic structures, sometimes complex, sometimes brilliantly simple, catching the eye of the consumer by their adventurous shapes. I made a (not complete) overview of the most eye-catching paperboard packages, not in terms of graphics, but in terms of structure.

The recent past has seen very interesting creations in folding cardboard or better still folding paperboard. It is as if the Japanese origami culture and the traditional Chinese paper cutting have influenced many a packaging designer. This means that some packages made from paperboard have the most fantastic structures, sometimes complex, sometimes brilliantly simple, catching the eye of the consumer by their adventurous shapes. I made a (not complete) overview of the most eye-catching paperboard packages, not in terms of graphics, but in terms of structure.

Örflögur microchips are healthy, no fat potato chips. They are not fried, but baked and dried and salted with the sea. A pure product of nature. This Icelandic brand of chips eliminated the problem of the loud crunchy noise of chips bags, as well as the dirty hands digging into shallow chip bags. Its packaging is a box that folds out into a bowl.

Örflögur microchips are healthy, no fat potato chips. They are not fried, but baked and dried and salted with the sea. A pure product of nature. This Icelandic brand of chips eliminated the problem of the loud crunchy noise of chips bags, as well as the dirty hands digging into shallow chip bags. Its packaging is a box that folds out into a bowl.

Achieving an environmentally responsible package starts with the material. Tetra Pak is made entirely from recycled and/or renewable resources that are also 100% recyclable. The designers applied an uncoated, untreated paper to the outside of the container, adding a distinguished, earthy aesthetic that not only captures the attention of the environmentally conscious consumer but stands out on the shelf amid other cartons as well. The aseptic component of the Tetra Pak allows the Organic Valley shelf-stable line of organic milk to be distributed and stored without the use of refrigeration.

Achieving an environmentally responsible package starts with the material. Tetra Pak is made entirely from recycled and/or renewable resources that are also 100% recyclable. The designers applied an uncoated, untreated paper to the outside of the container, adding a distinguished, earthy aesthetic that not only captures the attention of the environmentally conscious consumer but stands out on the shelf amid other cartons as well. The aseptic component of the Tetra Pak allows the Organic Valley shelf-stable line of organic milk to be distributed and stored without the use of refrigeration. This year at the Salone Internazionale del Mobile (Milan, Italy, April 12-17), during Veuve Clicquot’s Milan Yellow Week,

This year at the Salone Internazionale del Mobile (Milan, Italy, April 12-17), during Veuve Clicquot’s Milan Yellow Week,

Sushi, the famous Japanese dish from decorative fresh fish products, has not only to be superb of taste, but it has to be much more. It has to appeal as much to the eye as to the palate. It has to be fresh, perfect of taste and please the eye. In other words the packaging complements the perfection.

Sushi, the famous Japanese dish from decorative fresh fish products, has not only to be superb of taste, but it has to be much more. It has to appeal as much to the eye as to the palate. It has to be fresh, perfect of taste and please the eye. In other words the packaging complements the perfection.

In the same style as the Danish design is the Sta-Pack created by PT Bukit Muria Jaya/BMJ in Indonesia. Not quite the same, as the Sta-Pack consists of several separate units with an added handle. It certainly is a nice and elegant solution as fast food packaging, especially for the take-away market of upscale meals.

In the same style as the Danish design is the Sta-Pack created by PT Bukit Muria Jaya/BMJ in Indonesia. Not quite the same, as the Sta-Pack consists of several separate units with an added handle. It certainly is a nice and elegant solution as fast food packaging, especially for the take-away market of upscale meals.

I wrote about this packaging in a previous article, not long ago, but it is such a beautiful construction that it can easily be adapted to take-out meals.

I wrote about this packaging in a previous article, not long ago, but it is such a beautiful construction that it can easily be adapted to take-out meals.

Two years ago I wrote about a new development as a result of a collaboration of some Brazilian packaging companies. The

Two years ago I wrote about a new development as a result of a collaboration of some Brazilian packaging companies. The

Australian company

Australian company  In Europe, around the 1900s, a paper-like substance was originally known as rice paper, due to the mistaken notion that it was made from rice. In fact, it consisted of the pith of a small tree, Tetrapanax papyrifer, the rice paper plant.

In Europe, around the 1900s, a paper-like substance was originally known as rice paper, due to the mistaken notion that it was made from rice. In fact, it consisted of the pith of a small tree, Tetrapanax papyrifer, the rice paper plant.

It’s based on the oval or circular peel-off labels fixed to the skins of fruits, however the labels essentially dissolve into an organic soap mixture which can then be used as a cleaning product, partly aiding in the removal of substances from the fruit or vegetable’s surface.

It’s based on the oval or circular peel-off labels fixed to the skins of fruits, however the labels essentially dissolve into an organic soap mixture which can then be used as a cleaning product, partly aiding in the removal of substances from the fruit or vegetable’s surface.